OEM/ODM

Multi Manufacturing Capability

Producing Process

Understanding customer requirements/discussion.

Our company, backed by extensive manufacturing experience, systematically reviews and discusses the product requirements presented by OEM/ODM customers. This includes examining the manufacturability of product (part) designs, defining detailed process arrangements, selecting materials or other components, establishing the framework for inspection and quality assurance, addressing packaging and special transportation requirements, and even reviewing collaboration contracts. The goal is to ensure that before the project commences, both parties have a comprehensive understanding of the entire project.

Product design proposal

ODM products involve more of our company's know-how, and thus, during the product development process, our R&D unit and assigned engineers proactively propose ideas at various stages of the project. They provide 2D/3D drawings to illustrate design concepts and details for in-depth discussions and verification. The aim is to achieve a shared design consensus between both parties before the prototyping phase, ensuring that a thorough understanding of the product or service design is reached.

Product prototyping

Prototype sampling places a significant emphasis on timeliness in our company. Our development process involves the operation of cross-departmental integrated project teams. Combined with the robust and rapid sampling capabilities provided by a complete supply chain system, the sampling process follows a comprehensive set of steps, including quoting for the prototype, issuing drawings, incoming material inspection, assembly testing, and writing experimental reports. The packaging and transportation during the sampling process, as well as the records and subsequent adjustments discussed by both parties, are part of a thorough implementation process to ensure the success of the sampling procedure.

Sample confirmation

Our company has meticulously planned a comprehensive process for OEM/ODM product sampling operations. This includes product specification verification, data reporting, outbound packaging design planning, the creation of standardized production process documents, and the collection of various certification requirement data. The primary goal is to enable customers to quickly pass mass production approval, assisting them in swiftly launching production and entering the market.

Production manufacturing

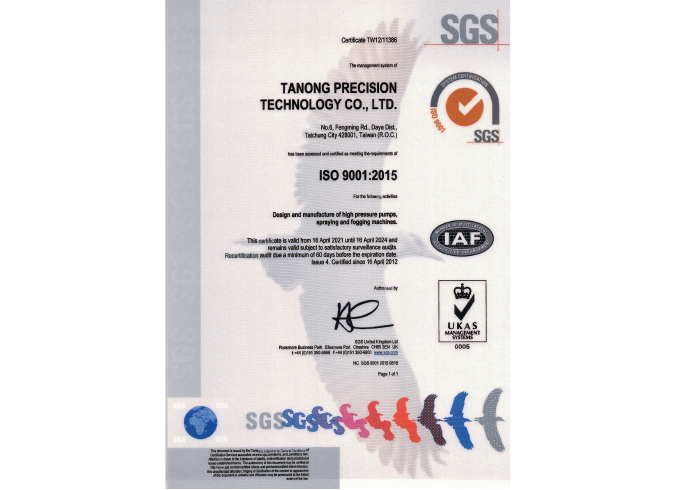

For the manufacturing of OEM/ODM products, whether through outsourcing or in-house assembly and testing processes, we strictly adhere to the Standard Operating Procedures (SOP) established and reviewed during the development process. The procurement and quality assurance departments provide production process guidance and supervision for our partner manufacturers. The in-house production units also adhere to the quality system framework of ISO 9001, implementing production details to ensure that we produce qualified products according to specified manufacturing processes.

Quality control inspection

Our company adheres to the principle of preventive management in the production process of products. For outsourced production, the management company establishes an SQE (Supplier Quality Engineering) unit. This unit pre-plans control methods and measuring tools for the manufacturing process, assists manufacturers in creating SOP/SIP documents, and provides on-site personnel education. The outgoing quality control (OQC) of the supplier is integrated with our incoming quality control (IQC), connecting to the in-house process's in-process quality control (IPQC) and final quality control (FQC). This seamless process quality control is established to ensure the quality of every aspect of production.

Finished product shipment

<br /> Our company also provides packaging design for OEM/ODM products. The design is based on considerations for impact protection and corrosion prevention, taking into account transportation costs. We align the packaging design with economical sea and air transportation plans and an immediate shipment policy. This ensures that customers can obtain the required quantity of OEM/ODM products within the optimal timeframe.

CUSTOM SERVICE

Our commitment to innovative research and development is evident in many groundbreaking products, such as Taiwan's first movable atomizing fan and Taiwan's earliest domestically developed high-pressure central water supply system. Leveraging our solid technical capabilities and a keen sense of market demand, Big Farm continually explores and develops innovative products that offer unique user experiences. This forms the foundation of our commitment to the sustainable operation of the company in the future.

-

Precision Inspection Capability

-

Research & Development Capability

-

Precision Machining and Manufacturing

-

Multi Manufacturing Capability

-

Rich market experience

Equipments

- Raw material warehouse zone

- Factory area