Product

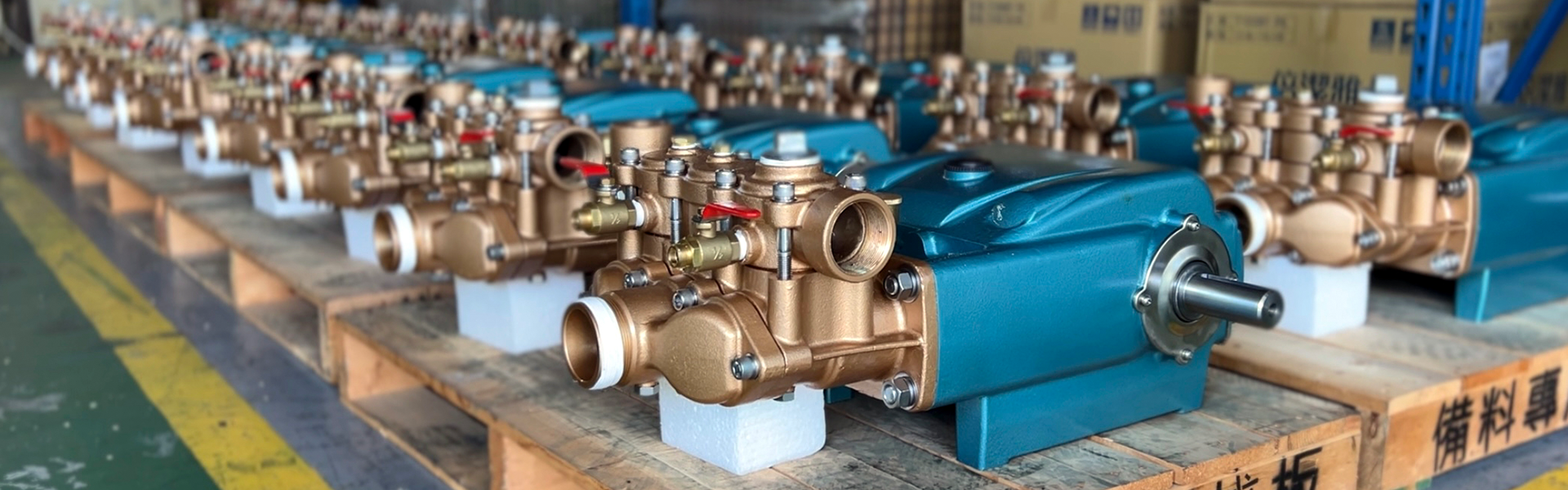

High-Pressure Triplex & Plunger Pumps

How High-Pressure Triplex Plunger Pumps Work

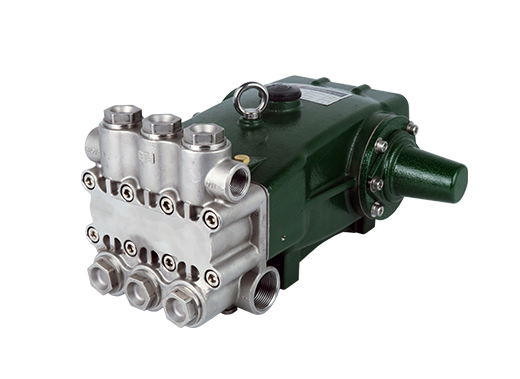

A triplex plunger pump is a type of positive displacement pump that moves fluid by mechanical action, converting it into hydraulic energy. While many pump types exist—such as piston, gear, and multistage centrifugal pumps—our specialty lies in high-pressure pumps. Our models are primarily crankshaft-driven, reciprocating triplex plunger pumps, complemented by a selection of piston pumps and radial axial block driven pumps.

Our pumps' capabilities range as follows:

- Working pressure: 0 – 300 bar (up to 4350 PSI)

- Flowrate: 250 ml/min – 270 L/min

- Required HP: ¼ HP – 60 HP

Applications of Triplex Plunger Pumps

High-pressure triplex pumps generate intense fluid pressure through a series of mechanical actions, transferring energy from the power source to the plunger and ultimately to the fluid. When combined with various specialized nozzles, this high-pressure fluid can be utilized for the following applications:

Misting

Applications include cooling, humidification, dust suppression, disinfection, fire control, disease prevention, and creating special landscape effects.

Cleaning

Ideal for vehicle washing, environmental cleaning, and various industrial cleaning tasks.

Waterjet Cutting

Fluid Delivery

Used for high-pressure boiler feed water, oil well feed water, and more.

Our high-pressure pump systems are constructed from a variety of devices, electrical components, and logic control units. Different frameworks are engineered to meet specific customer needs, encompassing the high-pressure pump, driving power source, drive mechanism, pressure and logic control units, tubing design, electrical wiring, housing, and safety features.

Triplex Plunger Pump Specifications

Our high-pressure pumps are crankshaft-driven triplex plunger pumps, available in three main categories:

Professional Use

These pumps run at RPMs below 1000, typically driven by a pulley belt (direct drive with 6P/8P induction or inverter motors also available). They integrate with PLCs or advanced control systems and sensors to form a complete logical system. Recommended for 24/7 industrial operations, their low RPM operation extends the life of wearable parts and lubricant, reducing maintenance frequency.

Semi-professional Use

Operating between 1450 and 2000 RPM, these are often in direct drive (powered by a 4P induction motor or a low-RPM engine). Combined with a simple control panel, this category is ideal for high-pressure cleaning machines and basic systems for low-intensity commercial use. The medium working RPM leads to faster wear on parts and requires more frequent oil changes compared to professional models, resulting in slightly higher maintenance costs.

DIY Home Use

Running at RPMs higher than 2500, these pumps are mostly direct-drive (using a 2P induction motor or high-RPM engine) and operated by a simple on/off switch with basic accessories. With a guaranteed life cycle of less than 200 hours, they are recommended for home or infrequent use, for no more than one hour of consecutive work.